In the realm of food science, understanding the functional properties of ingredients is crucial for product development and quality control. Mung bean starch, a staple in many Asian cuisines, has gained attention for its unique gelling characteristics, particularly in the production of cold dishes like liangfen (Chinese cold jelly). Recent laboratory studies have focused on quantifying the elastic properties of mung bean starch gels, revealing fascinating insights into its molecular behavior and culinary applications.

The gelatinization process of mung bean starch differs significantly from common starches like corn or potato. When subjected to controlled heating and cooling cycles, mung bean starch forms translucent gels with remarkable springiness. Food rheologists have developed specialized testing protocols using texture analyzers to measure this elasticity without compromising the delicate gel structure. These measurements typically involve calculating the gel's ability to recover its original shape after deformation, a property that chefs describe as "bite" or "mouthfeel."

Laboratory findings indicate that the elastic modulus of mung bean starch gels shows unusual temperature dependence. Unlike many other starches that lose elasticity when chilled, properly prepared mung bean gels actually increase their springiness at refrigeration temperatures. This explains why traditional recipes always emphasize serving liangfen cold. The crystalline regions in the starch granules appear to reorganize during the cooling phase, creating a three-dimensional network that traps water molecules while maintaining structural integrity.

Moisture content plays a pivotal role in the final texture of the gel. Through precise water-starch ratio experiments, researchers have identified an optimal hydration window between 1:5 and 1:6 (starch to water) for maximum elasticity. Beyond this range, the gels either become too brittle or lose their characteristic bounce. This explains why traditional recipes passed down through generations often specify water measurements so precisely, even if the practitioners didn't understand the scientific basis.

The pH level of the preparation water emerges as another critical factor affecting gel strength. Slightly alkaline conditions (pH 7.5-8.5) significantly enhance the elastic properties compared to neutral or acidic environments. This phenomenon correlates with historical practices in certain regions where cooks would add a pinch of wood ash to the mixture. Modern testing confirms that the mild alkalinity helps stabilize the amylopectin networks responsible for the gel's rubbery texture.

Interestingly, the particle size distribution of the starch powder shows measurable effects on the final product's characteristics. Finer particles with consistent granule size produce gels with more uniform elasticity throughout the matrix. This finding has led to improved milling techniques in commercial production facilities, where achieving particle size uniformity has become a quality benchmark. The relationship between granule size and gel strength appears nonlinear, with optimal results occurring in a specific middle range rather than at either extreme.

Storage conditions post-gelation dramatically influence the maintenance of elastic properties. Research demonstrates that properly wrapped gels maintain their springiness for up to 72 hours when kept at 4°C, while exposure to air causes rapid surface dehydration and texture degradation. This has important implications for both home cooks and food manufacturers regarding packaging and shelf life considerations. The studies also reveal that second-day liangfen actually develops improved texture due to continued slow retrogradation of starch molecules.

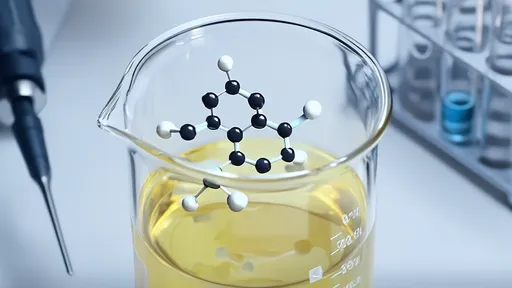

Comparative studies with other legume starches highlight mung bean's unique position. While pea and chickpea starches can form firm gels, they lack the distinctive elastic recovery that makes mung bean products so desirable. The difference appears rooted in the amylose-amylopectin ratio and the specific branching patterns of the mung bean starch molecules. These structural nuances explain why substitutions in traditional recipes often yield unsatisfactory results despite similar apparent textures when freshly made.

Emerging applications are exploring modified versions of mung bean starch gels for specialized dietary needs. The starch's natural elasticity makes it an attractive base for texture-modified foods in dysphagia diets, where the right balance of firmness and melt-in-mouth properties is crucial. Food engineers are experimenting with controlled enzymatic treatments to fine-tune the gel strength while maintaining the clean flavor profile that makes mung bean products so versatile.

Traditional preparation methods have been scrutinized through the lens of modern food chemistry. The centuries-old practice of repeated washing and settling to extract pure starch aligns perfectly with what scientists now understand about protein content interference with gel formation. Even small amounts of residual protein can disrupt the crystalline starch networks, reducing elasticity. This synergy between ancestral knowledge and scientific validation presents fascinating case studies in the evolution of food preparation techniques.

Future research directions aim to unravel the molecular basis of mung bean starch's exceptional gelling properties. Advanced techniques like small-angle X-ray scattering (SAXS) and nuclear magnetic resonance (NMR) are being employed to visualize the nanostructure of the gel networks. Preliminary data suggest that the alignment of amylopectin side chains in mung bean starch may create more numerous but shorter crystalline regions compared to other starches, potentially explaining its unique rubbery yet tender texture.

The implications of these findings extend beyond culinary applications into materials science. The biodegradable nature of starch-based gels combined with mung bean starch's mechanical properties has sparked interest in developing edible packaging films and biomedical scaffolds. As research continues, the humble mung bean starch may transition from a kitchen staple to a multifunctional biomaterial with applications spanning gastronomy to sustainable technology.

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025