In the bustling night markets of Hong Kong and the family-run eateries of Guangzhou, the sizzle of clay pot rice being prepared signals more than just another meal—it represents a centuries-old culinary tradition where texture reigns supreme. At the heart of this beloved dish lies a scientific marvel: the amylose content of indica rice, which holds the key to achieving those prized separate, non-sticky grains that define authentic clay pot rice.

The Science Behind the Sizzle

When chefs lift the lid of a properly cooked clay pot rice, the visual and textural harmony of distinctly separate grains creates an almost musical effect—each kernel maintaining its integrity while contributing to the whole. This culinary alchemy stems from indica rice's unique starch composition, particularly its amylose levels typically ranging between 22-28%. Unlike their glutinous rice counterparts with near-zero amylose, these medium-to-long grain varieties undergo dramatic transformations during cooking that professional chefs have learned to harness through generations of trial and error.

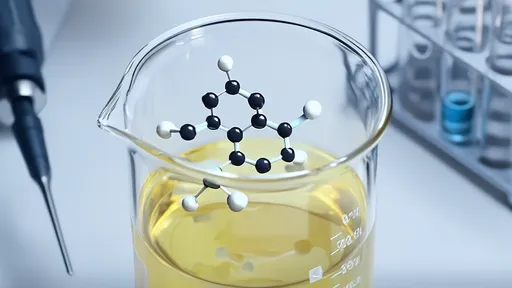

The magic begins when heat and water penetrate the rice's cellular structure. Amylose molecules, being linear chains of glucose, align themselves in orderly formations that create firm gel structures. As the rice cooks, these molecules leach out and form new bonds between granules, but crucially—in proper clay pot rice—without causing excessive stickiness. The result is what Cantonese chefs describe as "san fen ming bai" (三分明白), literally meaning "three parts clarity," referring to the ideal separation where grains remain distinct yet perfectly cooked.

Regional Variations and Agricultural Secrets

Across Southern China's rice-growing regions, subtle differences in soil composition and climate create variations in amylose content that local cooks have learned to exploit. The Pearl River Delta's alluvial plains produce rice with slightly lower amylose (22-24%), yielding a tender-but-separated texture preferred in Hong Kong-style clay pot rice. Meanwhile, upland varieties from Guangxi province often test at 26-28% amylose, giving their grains more structural integrity—a characteristic prized in Hakka-style preparations where crisper textures are desired.

Modern rice breeding programs have identified specific genetic markers linked to optimal amylose expression for clay pot cooking. The Wx gene, controlling granule-bound starch synthase activity, has become a focal point for agronomists developing new cultivars. "What farmers call 'clay pot friendly' rice actually has very specific genetic signatures," explains Dr. Liang Wei, a rice geneticist at South China Agricultural University. "We're now able to predict amylose content within 0.5% accuracy at the seedling stage."

The Water Ratio Paradox

Seasoned clay pot rice masters understand that amylose content directly dictates their water measurements—but in counterintuitive ways. While one might assume higher-amylose rice requires more water to compensate for its dryness, the opposite proves true in practice. Rice with 25% amylose typically needs a 1:1.1 rice-to-water ratio, whereas 22% amylose varieties perform better at 1:1.3. This inverse relationship stems from amylose's water absorption kinetics during the critical gelatinization phase between 60-80°C.

Professional kitchens often maintain separate water measurement systems for different rice batches. At the Michelin-starred Yue restaurant in Guangzhou, chefs use color-coded measuring cups corresponding to that day's rice amylose readings. "Last month's harvest from Taishan needed blue cups (1:1.15), but this week's shipment from Zhaoqing requires green cups (1:1.25)," reveals head chef Huang Ming. "The difference seems small, but it's what separates good clay pot rice from exceptional."

Thermal Dynamics of the Clay Pot

The unglazed clay pot itself plays an active role in managing amylose behavior. As heat radiates through the porous ceramic, it creates multiple temperature zones that cleverly stage the starch's transformation. The bottom layer reaches 110-130°C, where amylose rapidly dehydrates to form the prized crispy crust (guo ba). Meanwhile, the middle portion maintains a steady 95-100°C for controlled gelatinization, while the top layer's milder 80-90°C allows gradual water absorption without bursting the grains.

This thermal stratification explains why even premium high-amylose rice fails to achieve proper separation in modern rice cookers. "Electric cookers homogenize the temperature, forcing all the amylose to behave the same way," laments Chef Chen of Guangzhou's historic Lian Xiang Lou restaurant. "The clay pot's uneven heating is what allows each grain to find its perfect state."

The Aging Factor

Amylose content isn't static—it evolves during rice storage in ways that significantly impact clay pot performance. Newly harvested rice contains more amorphous starch regions that absorb water unpredictably. After 3-6 months of controlled storage, the amylose molecules undergo gradual crystallization that yields more consistent separation. Traditional rice shops along Guangzhou's Qingping Market still maintain temperature-controlled granaries where chefs select rice aged to their exact specifications.

Recent studies at Guangdong Academy of Agricultural Sciences revealed that properly aged high-amylose rice develops enhanced resistant starch (RS3) formations. These thermally stable amylose-lipid complexes contribute to the dish's signature al dente texture while offering digestive health benefits. "Our ancestors didn't know about RS3, but they recognized that 'last season's rice' made better clay pot rice," notes food historian Professor Zhang Li.

Modern Challenges and Innovations

Climate change poses new challenges to maintaining consistent amylose levels. Rising nighttime temperatures during rice's grain-filling period can depress amylose content by 2-3 percentage points—enough to ruin batch after batch of clay pot rice. Forward-thinking restaurants now work directly with meteorologists and agronomists to adjust their rice sourcing throughout the season.

Some innovators are taking matters into their own hands. At Shenzhen's Riceology Lab, food scientists have developed amylose-boosting pre-treatment techniques using controlled humidity and infrared exposure. Their "Amylo-Tune" process can adjust rice amylose within a 2% range, offering chefs unprecedented control over grain separation. Meanwhile, traditionalists argue such interventions undermine the agricultural artistry that made clay pot rice special in the first place.

As diners worldwide develop more sophisticated palates, understanding these scientific nuances becomes increasingly valuable. The next time you hear that characteristic sizzle and lift the lid to see perfectly separate grains glistening in the clay pot, remember—you're witnessing centuries of culinary wisdom and cutting-edge food science working in perfect harmony, one amylose molecule at a time.

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025

By /Jul 24, 2025